Mercedes factory welding methods incorporate advanced techniques that prioritize strength, durability, and lightweight design. By using strategic material selection, including aluminium alloys, and employing precise welding with skilled technicians, Mercedes ensures every vehicle body shop meets their high standards. This meticulous approach underpins the brand's reputation for top-tier quality in automotive body work, enhancing fuel efficiency, structural integrity, and overall vehicle performance.

Mercedes-Benz, renowned for its luxury and performance, employs advanced factory welding methods that seamlessly combine strength and lightweight design. This article explores the innovative techniques, material choices, and precision engineering that underpin these cutting-edge practices. Discover how Mercedes optimizes vehicle performance while maintaining structural integrity, setting a new standard in automotive manufacturing. Learn about the specific methods used in their factories to achieve both strength and reduced weight.

- Advanced Techniques for Strength and Durability

- Material Selection: Lightweight without Compromise

- Precision Engineering for Optimal Performance

Advanced Techniques for Strength and Durability

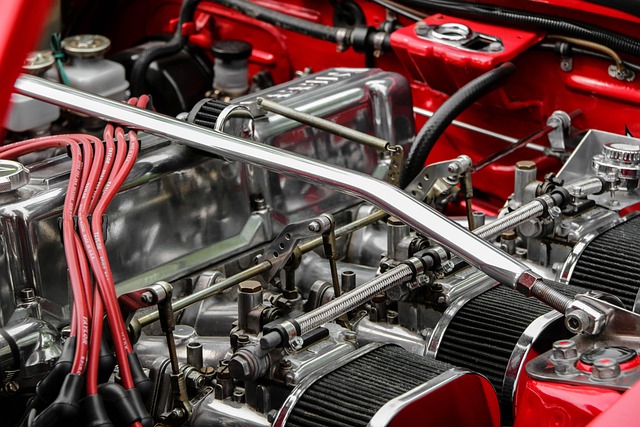

Mercedes factory welding methods have evolved significantly, incorporating advanced techniques that enhance both strength and durability. These cutting-edge approaches ensure that every vehicle body shop or automotive body work performed aligns perfectly with the brand’s reputation for excellence. By combining precision engineering with state-of-the-art equipment, Mercedes creates structures that are not just robust but also lightweight.

This meticulous process involves specialized welding techniques tailored to different materials and components. The result is a seamless fusion that surpasses industry standards, ensuring every vehicle assembled meets the highest safety requirements. These advanced methods reflect the company’s commitment to innovation, making them a game-changer in the automotive body shop landscape.

Material Selection: Lightweight without Compromise

Mercedes factory welding methods prioritize material selection to achieve both strength and lightweight design without compromising on quality or performance. The automotive giant understands that the right materials are key to creating efficient, durable vehicles. Aluminium alloys, for instance, have become a preferred choice due to their excellent weight-to-strength ratio, enabling lighter structures without sacrificing structural integrity—a crucial aspect in modern car manufacturing.

These advanced welding techniques, employed by skilled technicians, ensure precise and robust connections between components. The result is a vehicle body that is both sturdy and lightweight, enhancing fuel efficiency and overall performance. This meticulous approach to material selection and factory welding methods underscores Mercedes’ commitment to delivering top-tier quality in their car repair services and vehicle repair services, ensuring each automobile meets the highest safety standards while remaining competitive in the market.

Precision Engineering for Optimal Performance

Mercedes factory welding methods are renowned for their precision engineering, which significantly contributes to the optimal performance and overall quality of their vehicles. These advanced techniques go beyond simple joining of metal parts; they involve meticulous calculations and careful consideration of factors such as material properties, joint design, and environmental conditions. By employing state-of-the-art equipment and highly trained technicians, Mercedes ensures that every weld is consistent and accurate, meeting stringent safety and performance standards.

This level of precision engineering translates directly into enhanced structural integrity and reduced weight in final products. In the automotive restoration or collision repair services sectors, where car bodywork services are paramount, Mercedes’ welding methods serve as a benchmark for excellence. Their approach not only facilitates lighter vehicles but also improves fuel efficiency and overall vehicle dynamics, providing drivers with safer and more responsive driving experiences.

Mercedes factory welding methods combine advanced techniques, strategic material selection, and precision engineering to deliver both exceptional strength and lightweight design. These innovative practices ensure that every component not only meets rigorous safety standards but also enhances vehicle performance and efficiency. By mastering these methods, Mercedes continues to set the benchmark for excellence in automotive manufacturing.