Mercedes-Benz utilizes cutting-edge Mercedes factory welding methods for aluminum and boron steel, enhancing structural integrity and vehicle aesthetics while enabling efficient collision repairs. Their advanced techniques like laser welding and robotic resistance spot welding contribute to lightweight designs, superior corrosion resistance, and enhanced overall performance. This dedication to innovative manufacturing processes sets Mercedes apart in the automotive industry.

Mercedes-Benz, renowned for its automotive innovation, employs advanced welding techniques to construct its vehicles. This article delves into the specific manufacturing processes used by Mercedes, focusing on their aluminum and boron steel welding methods. By exploring these cutting-edge practices, we gain insights into how the brand maintains superior quality and precision in modern automotive production. Understanding these factory welding methods offers a glimpse into the future of vehicle fabrication, where materials science and engineering converge.

- Understanding Mercedes' Aluminum Welding Techniques

- Boron Steel: The Metal of Choice for Mercedes Manufacturing

- Advanced Welding Processes in Modern Automotive Production

Understanding Mercedes' Aluminum Welding Techniques

Mercedes is renowned for its innovative manufacturing processes, especially when it comes to working with advanced materials like aluminum and boron steel. Understanding their welding techniques offers insight into why their vehicles are known for durability and precision. The automaker employs a range of state-of-the-art Mercedes factory welding methods tailored to each unique metal.

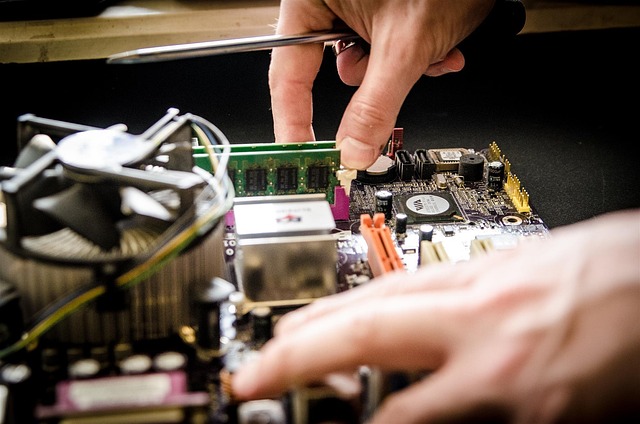

When it comes to aluminum, Mercedes utilizes specialized processes such as laser welding and robotic resistance spot welding. These methods ensure precise, strong bonds that maintain the structural integrity of the vehicle while also contributing to its lightweight design—a key aspect in modern automotive engineering. This attention to detail is evident, even when considering tasks beyond regular auto maintenance or repairs at an auto collision center, like achieving a perfect finish with minimal signs of welding on exterior panels, thanks to techniques that enable paintless dent repair.

Boron Steel: The Metal of Choice for Mercedes Manufacturing

In the realm of automotive manufacturing, Mercedes-Benz has long been recognized for its commitment to quality and innovation. One significant aspect of their production process is the strategic use of various metals, with Boron Steel emerging as the metal of choice in many critical components. This superalloy, known for its exceptional strength and durability, plays a pivotal role in Mercedes’ advanced welding techniques.

The integration of Boron Steel into vehicle construction has revolutionized the industry, particularly in areas such as bumper repair and collision center operations. Its enhanced resistance to corrosion and exceptional mechanical properties make it ideal for complex manufacturing processes like Mercedes factory welding methods. This metal’s versatility allows engineers to create lighter, more robust structures, contributing to improved fuel efficiency and overall vehicle performance.

Advanced Welding Processes in Modern Automotive Production

In the realm of modern automotive production, advanced welding processes have emerged as game changers, revolutionizing how vehicle components are joined. Mercedes factory welding methods stand at the forefront of this technological evolution, employing cutting-edge techniques to ensure precision, strength, and efficiency. These state-of-the-art methods extend far beyond traditional welding practices, incorporating specialized technologies such as laser welding and robotic arms that enable intricate and seamless connections. By adopting these advanced processes, automakers like Mercedes can achieve unparalleled quality control, reduce manufacturing times, and minimize the risk of human error—all crucial factors in today’s competitive market.

When it comes to materials, modern auto frame repair often involves a mix of aluminum and boron steel, each presenting unique welding challenges. Mercedes has tailored its factory welding methods to accommodate these materials’ distinct properties. Aluminum, known for its lightweight yet robust nature, requires precise control to prevent heat-related distortions during the welding process. Boron steel, on the other hand, demands specific welding techniques to manage its high strength and hardness while maintaining structural integrity. Through continuous innovation, Mercedes has mastered these welding intricacies, ensuring that auto collision repair and vehicle dent repair processes remain seamless, effective, and safe.

Mercedes-Benz has pioneered innovative Mercedes factory welding methods for both aluminum and boron steel, revolutionizing automotive production. By leveraging cutting-edge technologies, the company ensures superior structural integrity and lightweight designs in their vehicles. These advanced Mercedes factory welding methods play a crucial role in enhancing fuel efficiency and performance while maintaining the iconic quality and safety standards associated with Mercedes-Benz.